Fuel system inspections are critical for ensuring vessel safety, preventing fires, and maintaining environmental compliance in maritime operations. This comprehensive fuel system inspection checklist helps engineers and marine personnel systematically examine all fuel handling components, storage tanks, and transfer systems. Regular marine fuel inspections ensure MARPOL and SOLAS compliance while preventing fuel contamination, reducing equipment failures, and protecting crew safety from fire and explosion hazards. Start your free digital inspection trial

Importance of Fuel System Inspections

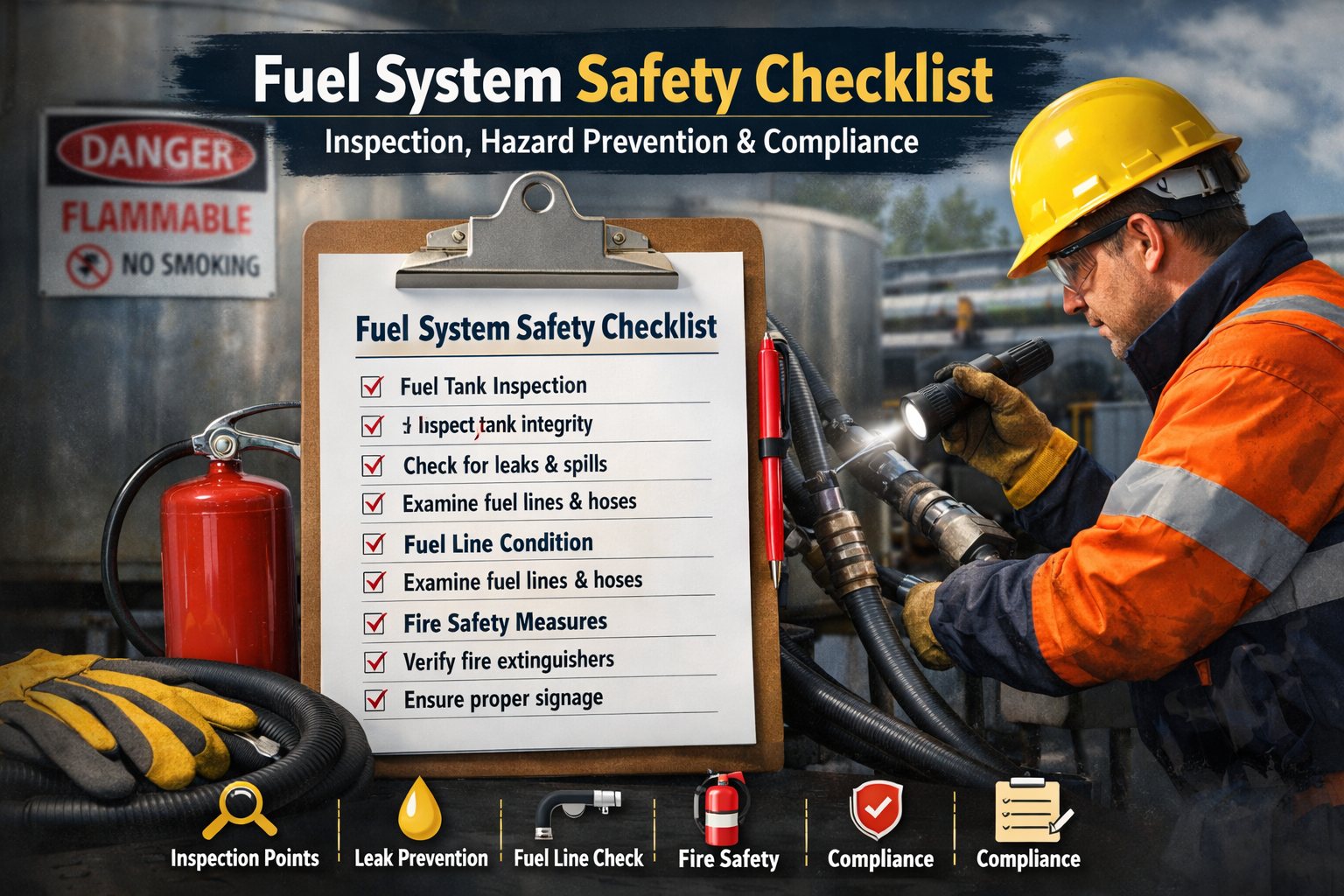

Safety & Fire Prevention

- Regular fuel system inspections prevent fires and explosions, identify leaks before they escalate, ensure proper fuel handling procedures, and protect crew from hazardous fuel exposure, maintaining safe vessel operations and preventing catastrophic incidents.

Environmental Compliance

- Systematic marine fuel inspections ensure MARPOL Annex VI compliance, prevent environmental pollution, maintain accurate fuel oil records and bunker delivery notes, and demonstrate proper fuel handling procedures required for regulatory compliance and vessel certification.

Equipment Reliability

- Proactive fuel system monitoring prevents fuel contamination, reduces engine failures from poor fuel quality, extends purification equipment lifespan, optimizes fuel efficiency, and ensures reliable fuel delivery to all consumers aboard the vessel.

Cost Management

- Following this bunker fuel safety checklist helps identify filter degradation and contamination issues early, prevents costly engine damage from contaminated fuel, reduces environmental penalties, minimizes fuel wastage, and ensures efficient fuel system operation throughout the vessel.

Sign up to track fuel system inspections automatically

Vessel Information

Pro Tips for Effective Fuel System Inspection

- ✓ MARPOL Compliance: Ensure all fuel handling procedures comply with MARPOL Annex VI requirements. Maintain accurate fuel oil records and bunker delivery notes (BDN) for a minimum of three years.

- ✓ Fuel Sampling: Always collect representative fuel samples during bunkering operations. Retain samples for analysis and dispute resolution. Use approved sampling points and containers.

- ✓ Leak Prevention: For ship leak detection compliance, pay special attention to fuel line joints, valve glands, and sight glass fittings. Use drip trays and regularly inspect for signs of weepage or active leaks.

- ✓ Fire Safety: Maintain proper housekeeping around fuel systems. Ensure quick-closing valves are tested regularly, fire detection systems are operational, and lagging on hot surfaces is intact to prevent fuel ignition.

1. FILTER INSPECTION

Fuel filter system inspection requirements:

Primary Filtration (Part 1)

Filter Systems (Part 2)

Maintenance Records (Part 3)

2. LEAK DETECTION FORM

Fuel system leak detection inspection requirements:

Piping & Connections (Part 1)

Containment & Cleanliness (Part 2)

Detection Systems (Part 3)

3. STORAGE TANKS

Fuel storage tank inspection requirements:

Tank Monitoring (Part 1)

Tank Equipment (Part 2)

Tank Safety (Part 3)

4. TRANSFER SYSTEM

Fuel transfer system inspection requirements:

Transfer Equipment (Part 1)

Piping Systems (Part 2)

Safety Systems (Part 3)

5. PURIFICATION SYSTEM

Fuel purification system inspection requirements:

Purifier Operation (Part 1)

Performance Monitoring (Part 2)

Maintenance Status (Part 3)

6. SERVICE SYSTEM

Fuel service system inspection requirements:

Service Tanks (Part 1)

Heating Systems (Part 2)

Quality Control (Part 3)

7. FIRE SAFETY

Fuel system fire safety inspection requirements:

Fire Prevention (Part 1)

Fire Protection (Part 2)

Emergency Systems (Part 3)

8. BUNKERING EQUIPMENT

Bunkering equipment inspection requirements:

Bunkering Systems (Part 1)

Spill Prevention (Part 2)

Bunkering Safety (Part 3)

9. FUEL DOCUMENTATION

Fuel documentation and record-keeping requirements:

MARPOL Records (Part 1)

Sampling & Testing (Part 2)

Maintenance Logs (Part 3)

✓ Navigate Fuel System Safety with Confidence: With 70+ fuel system inspection items across 9 critical system categories—staying compliant requires organized tracking and documentation. See how leading maritime operators maintain fuel safety and MARPOL compliance. Schedule your demo now to discover how automated fuel system inspection tracking, leak detection monitoring, and bunker fuel safety documentation can transform your fuel management.

Maintenance Schedule Guidelines

Daily Checks

- Sound all service and settling tanks

- Check filter differential pressures

- Monitor purifier operation and discharge

- Check fuel temperature and viscosity

- Visual inspection for leaks

- Record fuel consumption in log

Weekly Maintenance

- Drain water from settling tanks

- Test quick-closing valves operation

- Clean drip trays and save-alls

- Check tank vent flame screens

- Test fuel oil high level alarms

- Inspect flexible fuel hoses

Monthly Maintenance

- Change duplex filter elements

- Service fuel purifiers thoroughly

- Check fuel heater operation

- Calibrate viscosity controller

- Inspect transfer pump seals

- Review fuel analysis reports

Annual / Class Survey Requirements

- ✓ Complete fuel tank internal inspection and cleaning

- ✓ Overhaul fuel purifiers with bowl and disc replacement

- ✓ Test all quick-closing valve remote operations

- ✓ Calibrate flow meters and fuel measurement systems

- ✓ Update fuel system drawings and documentation

- ✓ Professional inspection by Classification Society surveyor

- ✓ Comprehensive pressure testing of fuel piping systems

- ✓ Review and update MARPOL compliance procedures

Why Use Digital Fleet Management for Fuel System Inspections?

MarineInspection App Benefits for Fuel System Management:

- ✓ Automate fuel system inspection schedules and MARPOL compliance tracking

- ✓ Maintain complete digital records for all fuel handling equipment

- ✓ Track filter performance and purifier maintenance schedules

- ✓ Store bunker delivery notes and fuel analysis reports digitally

- ✓ Generate reports for Classification Society surveys and PSC inspections

- ✓ Set automated reminders for leak detection and safety system testing

- ✓ Document fuel consumption trends and tank sounding records

- ✓ Monitor fuel quality parameters and viscosity control performance

Book a demo to see automated fuel system inspection tracking

Frequently Asked Questions About Fuel System Inspections

1. How often should fuel system inspections be conducted?

Fuel system inspections should be conducted daily for critical parameters including service tank levels, filter differential pressures, purifier operation, and visual leak detection. Weekly detailed inspections should cover settling tank water draining, quick-closing valve testing, and comprehensive leak detection. Monthly inspections include filter element changes, purifier servicing, and fuel quality analysis. The ISM Code and MARPOL Annex VI require documented fuel handling procedures and inspection frequency based on vessel type and fuel configuration.

2. What are the most critical items in fuel system inspections?

The most critical items include filter differential pressure monitoring to prevent engine fuel starvation, leak detection at all flanges and valve glands to prevent fires, fuel purifier operation to ensure fuel quality, quick-closing valve functionality for fire safety, tank level monitoring to prevent overflows, fuel quality testing for compliance with ISO 8217 standards, and proper functioning of all fire detection and suppression systems in fuel handling areas. These items directly impact vessel safety, environmental compliance, and engine reliability.

3. What regulations govern fuel system inspections?

Fuel system inspections are governed by MARPOL Annex VI (air pollution prevention), SOLAS Chapter II-2 (fire protection), ISM Code (safety management), Classification Society rules, ISO 8217 (fuel quality standards), and flag state regulations. MARPOL specifically requires retention of representative fuel samples, accurate bunker delivery notes, and documented oil record book entries. Vessels must demonstrate compliance with sulfur content limits and proper fuel changeover procedures when entering emission control areas (ECAs).

4. How should fuel samples be collected and retained?

Fuel samples must be collected during bunkering operations using approved sampling points and equipment. MARPOL requires retention of representative samples in sealed containers for at least 12 months. Samples should be taken continuously throughout the bunkering operation or as composite samples at regular intervals. The vessel must maintain a minimum of two sealed samples per bunker delivery - one for the ship and one that may be provided to authorities upon request. Proper labeling with date, location, and bunker details is mandatory.

5. What are the consequences of inadequate fuel system inspections?

Inadequate fuel system inspections can lead to engine failures from contaminated or poor-quality fuel, fires and explosions from fuel leaks near hot surfaces, environmental pollution from fuel spills or improper handling, MARPOL violations resulting in fines and vessel detention, damage to fuel injection equipment from water or particulate contamination, increased maintenance costs from preventable equipment failures, and PSC detentions for non-compliant fuel handling procedures. Regular inspections and proper documentation are essential for safe operations and regulatory compliance.

Take Action: Implement Comprehensive Fuel System Safety Management

Download our FREE Fuel System Safety Checklist and start implementing systematic fuel handling practices for your vessel. Integrating digital fleet management with your fuel system inspection routine ensures nothing is overlooked, maintains MARPOL compliance, and protects crew, vessel, and the environment. Experience the power of automated inspection tracking to prevent leaks, optimize fuel quality, and ensure safe, compliant fuel handling throughout your vessel's operations.

Ensure Fuel System Safety & Environmental Compliance Excellence

Comprehensive fuel system management: filters, leak detection, storage tanks, transfer systems, purification equipment, service systems, fire safety, bunkering operations—all tracked automatically for optimal safety and compliance with MARPOL, SOLAS, and IMO requirements.